For stain less steel and tool steel SUS304 & SUS316L.To produce well-designed cutting tools, which have both long life and high quality, equal emphases must be laid on the factors of the cutting tool material, product material as well as processing ways of the machines. All of our cutting tools are accordingly processed to the cut material, with appropriate cutting angle, and made from high-quality tungsten carbide. This measure not only prolongs the life of tools, enhances product quality, but also allows product to have greater wearing quality.Cut Materials: brass/bronze, low lead brass/bronze, brass/bronze pipe/tube, zinc alloy casting, iron, hardness iron, cast iron, steel, carbon steel, hardness carbon steel, aluminum die casting, aluminum alloy 6 system and 7 system, magnesium alloy, titanium alloy, plastic, carbon fiber CM, glass fiber CM, bakelite, and many more.To purchase or inquire price, please specify the desired cut materials (i.e. the material of the matter that will be cut by our products) for faster and more accurate service.

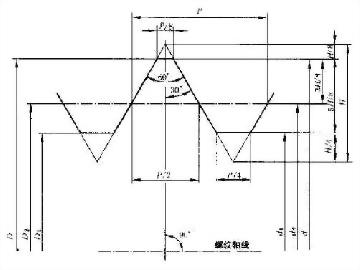

設計製作滿足自動化生產的高效能/高壽命/高精度等高經濟價值的鎢鋼直溝絲攻必須針對被加工件以下的參數特徵製作最適用的螺紋絲攻,

1.螺紋直徑&牙距 2.工件材質 3.通孔/盲孔 4.螺紋深度 5.品管檢驗要求

| 客戶需求確認單-範例 Customer Order Requirement List-Example | ||||||||

|

序號 NO. |

總類 Type |

螺紋規格-精度 Thread Size-class |

被削材質 Workpiece Material |

通孔/盲孔 Through / length |

螺紋深度 |

檢驗要求 Quality Control |

設備導程 Machine Pitch |

特殊要求 Special Request |

| 1 |

鈷高速鋼 HSS-Co Spiral Taps |

M10x1.5-6H |

不鏽鋼 SUS316L |

盲孔 Blind hole |

15mm |

通止規合格 Thred Gauge |

穩定 Stable |

牙規+塞規檢驗合格 |

| 2 |

鈷高速鋼 HSS-Co Spiral Taps |

3/4-16UNF-2B |

不銹鋼 |

通孔 Through hole |

20mm |

工作實配 Match workpiece |

不穩定 Through Unstable |

不穩定 Through Unstable |

本公司備有公制 M 螺紋 統一UN螺紋 惠氏W螺紋 管用螺紋 G PT PF PS NPSM NH NPT NPSL NPSF等各國螺紋標準規範,滿足使用者不同螺紋製造組合裝配之設計需求。

本公司生產多種絲攻標準柄,包含 JIS柄 DIN 柄 銑刀柄 ER筒夾柄 等多種絲攻柄選擇,可滿足不同設備之使用需求。

UN,UNC,UNF,UNEF,UNS,Unified Thread,Spiral Flutes Taps,Cobalt HSS

UN,UNC,UNF,UNEF,UNS,3/4-16UNF-SFT-C

|

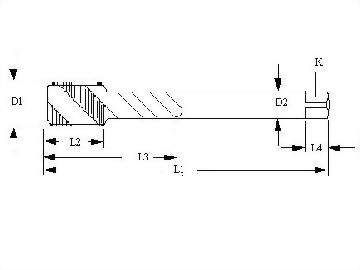

SpT.HC.UNC.J |

螺旋溝絲攻-高速鋼含鈷-統一螺紋ISO 2B標準-JIS柄 Spiral Flutes Taps - HSS.Co(M35) -Unified Corse Threads ISO 2B - JIS Shank |

||||||||||

|

統一粗螺紋UNC |

形狀 Shape |

工具參數 Tool Parameter |

|||||||||

|

公稱直徑 d1 mm |

牙距 Pitch TPI |

總長 L1 mm |

刃長 L2 mm |

工作長 L3 mm |

柄徑 d2 mm |

對邊 k mm |

邊長 L4 mm |

溝數 FN NO. |

精度 Class |

無效牙長 Chamfer Length |

工具參數 Parameter Remarks |

|

#8-32UNC |

32 |

50 |

10P |

|

5 |

4 |

7 |

4 |

2B |

III=2P |

A/B/C/O |

|

#10-24UNC |

24 |

60 |

10P |

|

5.5 |

4.5 |

7 |

4 |

2B |

III=2P |

A/B/C/O |

|

#12-24UNC |

24 |

60 |

10P |

|

6 |

4.5 |

7 |

4 |

2B |

III=2P |

A/B/C/O |

|

1/4-20UNC |

20 |

60 |

10P |

|

6 |

4.5 |

7 |

4 |

2B |

III=2P |

A/B/C/O |

|

5/16-18UNC |

18 |

70 |

10P |

|

6.1 |

5 |

8 |

4 |

2B |

III=2P |

A/B/C/CH |

|

3/8-16UNC |

16 |

75 |

10P |

3D |

7 |

5.5 |

8 |

4 |

2B |

III=2P |

A/B/C/CH |

|

7/16-14UNC |

14 |

80 |

10P |

3D |

8 |

6 |

9 |

4 |

2B |

III=2P |

A/B/C/CH |

|

1/2-13UNC |

13 |

85 |

10P |

3D |

9 |

7 |

10 |

4 |

2B |

III=2P |

A/B/C/CH |

|

9/16-12UNC |

12 |

90 |

10P |

3D |

10.5 |

8 |

11 |

4 |

2B |

III=2P |

A/B/C/CH |

|

5/8-11UNC |

11 |

95 |

10P |

3D |

12 |

9 |

12 |

4 |

2B |

III=2P |

A/B/C/CH |

|

3/4-10UNC |

10 |

105 |

10P |

3D |

14 |

11 |

14 |

4 |

2B |

III=2P |

A/B/C/CH |

|

7/8-9UNC |

9 |

115 |

10P |

3D |

17 |

13 |

16 |

4 |

2B |

III=2P |

A/B/C/CH |

|

1-8UNC |

8 |

125 |

10P |

3D |

20 |

15 |

18 |

4 |

2B |

III=2P |

A/B/C/CH |

|

1,1/8~2"UNC |

custom-made (https://www.ugmic.com.tw) (https://www.ugmic.com ) |

||||||||||

|

SpT.HC.UNF.J |

螺旋溝絲攻-高速鋼含鈷-統一細螺紋ISO 2B標準-JIS柄 Spiral Flutes Taps -HSS.Co(M35)-Unified Fine Threads ISO 2B - JIS Shank |

||||||||||

|

統一細螺紋UNF |

形狀 Shape |

工具參數 Tool Parameter |

|||||||||

|

公稱直徑 d1 mm |

牙距 Pitch TPI |

總長 L1 mm |

刃長 L2 mm |

工作長 L3 mm |

柄徑 d2 mm |

對邊 k mm |

邊長 L4 mm |

溝數 FN NO. |

精度 Class |

無效牙長 Chamfer Length |

工具參數 Parameter Remarks |

|

#8-36UNF |

32 |

50 |

10P |

|

5 |

4 |

7 |

4 |

2B |

III=2P |

A/B/C/O |

|

#10-32UNF |

24 |

60 |

10P |

|

5.5 |

4.5 |

7 |

4 |

2B |

III=2P |

A/B/C/O |

|

#12-28UNF |

24 |

60 |

10P |

|

6 |

4.5 |

7 |

4 |

2B |

III=2P |

A/B/C/O |

|

1/4-28UNF |

20 |

60 |

10P |

|

6 |

4.5 |

7 |

4 |

2B |

III=2P |

A/B/C/O |

|

5/16-24UNF |

18 |

70 |

10P |

|

6.1 |

5 |

8 |

4 |

2B |

III=2P |

A/B/C/CH |

|

3/8-24UNF |

24 |

75 |

10P |

3D |

7 |

5.5 |

8 |

4 |

2B |

III=2P |

A/B/C/CH |

|

7/16-20UNF |

20 |

80 |

10P |

3D |

8 |

6 |

9 |

4 |

2B |

III=2P |

A/B/C/CH |

|

1/2-20UNF |

20 |

85 |

10P |

3D |

9 |

7 |

10 |

4 |

2B |

III=2P |

A/B/C/CH |

|

9/16-18UNF |

18 |

90 |

10P |

3D |

10.5 |

8 |

11 |

4 |

2B |

III=2P |

A/B/C/CH |

|

5/8-18UNF |

18 |

95 |

10P |

3D |

12 |

9 |

12 |

4 |

2B |

III=2P |

A/B/C/CH |

|

3/4-16UNF |

16 |

105 |

10P |

3D |

14 |

11 |

14 |

4 |

2B |

III=2P |

A/B/C/CH |

|

7/8-14UNF |

14 |

115 |

10P |

3D |

17 |

13 |

16 |

4 |

2B |

III=2P |

A/B/C/CH |

|

1-12UNF |

12 |

125 |

10P |

3D |

20 |

15 |

18 |

4 |

2B |

III=2P |

A/B/C/CH |

|

1,1/8~1,1/2 UNX |

custom-made (https://www.ugmic.com.tw) +886-4-7788779 |

||||||||||

|

UGMIC reserves the right to modify the final dimension 有晙保留修改外型尺寸之權利 |

|||||||||||

|

SpT.HC.UNEF.J |

螺旋溝絲攻-高速鋼含鈷-統一極細螺紋ISO 2B標準-JIS柄 Spiral Flutes Taps-HSS.Co(M35)-Unified Extra Fine Threads ISO 2B - JIS Shank |

||||||||||

|

統一極細螺紋UNEF |

形狀 Shape |

工具參數 Tool Parameter |

|||||||||

|

公稱直徑 d1 mm |

牙距 Pitch TPI |

總長 L1 mm |

刃長 L2 mm |

工作長 L3 mm |

柄徑 d2 mm |

對邊 k mm |

邊長 L4 mm |

溝數 FN NO. |

精度 Class |

無效牙長 Chamfer Length |

工具參數 Parameter Remarks |

|

1/4-32UNEF |

20 |

60 |

10P |

|

6 |

4.5 |

7 |

4 |

2B |

III=2P |

A/B/C/O |

|

5/16-32UNEF |

18 |

70 |

10P |

|

6.1 |

5 |

8 |

4 |

2B |

III=2P |

A/B/C/CH |

|

3/8-32UNEF |

24 |

75 |

10P |

|

7 |

5.5 |

8 |

4 |

2B |

III=2P |

A/B/C/CH |

|

7/16-28UNEF |

20 |

80 |

10P |

|

8 |

6 |

9 |

4 |

2B |

III=2P |

A/B/C/CH |

|

1/2-28UNEF |

20 |

85 |

10P |

|

9 |

7 |

10 |

4 |

2B |

III=2P |

A/B/C/CH |

|

9/16-24UNEF |

24 |

90 |

10P |

3D |

10.5 |

8 |

11 |

4 |

2B |

III=2P |

A/B/C/CH |

|

5/8-24UNEF |

24 |

95 |

10P |

3D |

12 |

9 |

12 |

4 |

2B |

III=2P |

A/B/C/CH |

|

3/4-24UNEF |

24 |

105 |

10P |

3D |

14 |

11 |

14 |

4 |

2B |

III=2P |

A/B/C/CH |

|

7/8-20UNEF |

20 |

115 |

10P |

3D |

17 |

13 |

16 |

4 |

2B |

III=2P |

A/B/C/CH |

|

1-20UNEF |

20 |

125 |

10P |

3D |

20 |

15 |

18 |

4 |

2B |

III=2P |

A/B/C/CH |

|

1,1/8~1,1/2 UNX |

custom-made (https://www.ugmic.com.tw) +886-4-7788779 |

||||||||||

|

選用:□鍍鈦(Ti)□跳牙(X) Option :□Coated(Ti) □Interrupted(X) |

|||||||||||

UN,UNC,UNF,UNEF,UNS,3/4-16UNF-SFT-C

Solve the automation problems of CNC lathes, CNC milling machines and CNC special machines

1. It is easy to cause shrinkage holes after tapping, and the size is unstable (UGMIC spiral tapping can completely cut = reduce shrinkage holes problem).

2. Short service life, rapid shrinkage cavity problem, tooth gauge inspection = failure to pass through the gauge. (UGMIC can effectively reduce this problem)

3. When using an oversized tap, it is easy to stop the gauge from advancing and the gauge cannot be passed all the way through.

4. Requires heat treatment (UGMIC long super long-lasting spiral tapping completely cutting = reduce shrinkage cavity)

5. Surface treatment (Coating, Carburizing) is required, and the tap size can be controlled (customized products) to avoid secondary processing.

6. UGMIC products can meet CNC automated production, reduce the number of tool changes, and reduce overall costs.

7. UGMIC spiral spiral taps will be 7~15 times tool-life of general HSS taps

Satisfy inspection requirements & customized dimensions (rigid tapping & concentricity within 0.02mm) UGMIC accepts customized tap sizes, enlarged sizes, and sizes that meet actual process requirements, and OEM customization.。

Thread specifications that satisfy the needs of various industries (meet the requirements of pass-and-stop regulations and customized specification sizes)

General thread standards : M、UNC、UNF、UNEF、UN、UNS、W、BSW、BSF、…。

Pipe thread standards : PT、PF、PS、PJ(日本)、Rc、Rp、NPT、NPTF、PTF、NPS、NH、…。

Tire valve thread standard: V、CTV ; Bicycle thread standard : BC、BSC ;

trapezoid thread standards: TW、ACME、STUB、Tr。

The thread specifications are not detailed above. If necessary, we can provide specification evaluation and customization.

UN,UNC,UNF,UNEF,UNS,3/4-16UNF-SFT-C

Super long-lasting type [high-speed steel containing cobalt + spiral flutes tapps] long life, high precision, only better & more cost-effective!!

Applicable workpiece materials: high toughness, high ductility, high hole shrinkage

(rigid tapping & concentricity within 0.02mm)

1. Stainless Steel SUS304 ,SUS316L,SUS630 (Very good effect)

2. Hardness Steel HRC28~HRC45 (Very good effect)

3. High temperature alloy: titanium alloy T64, Inconel 718,Inconel 625

4. Ni-Cr-Mo steel, Tool steel, Carbon steel, iron, Aluminum, phosphor bronze, aluminum bronze (material with high toughness and ductility)

The above only lists the workpiece materials with obvious cost-effectiveness. More non-steel materials can also obtain high cost-effective results. Welcome to inquire!!